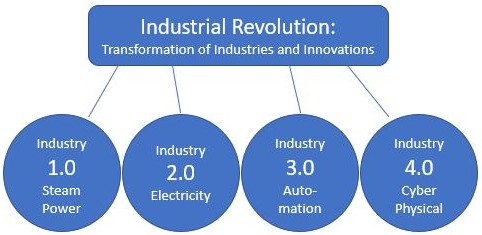

One of my favorite tasks at the end of each year is to do some planning for the coming year. With respect to Industry 4.0 there is so much to learn in 2019 and beyond. Conferences are a great way to supplement learning on this topic and this is a good time to plan for these conferences in your budget.

Conferences provide a way to sharpen your skills while away from regular work, meet experts face-to-face, network, and break out of your comfort zone.

Below is a list of conferences related to Industry 4.0 for the first half of 2019; some are in Pittsburgh, some in the USA, others are in foreign countries.

January

23th – 25th, Global Artificial Intelligence Conference, Santa Clara, USA

23rd – 26th, AI NEXTCon, Seattle, USA

26th – 29th, Applied Machine Learning Days, Lausanne, Switzerland

27th – Feb 1st, 33rd AAAI Conference on Artificial Intelligence, Honolulu, Hawaii, USA

February

22nd-24th, 11th International Conference on Machine Learning and Computing (ICMLC), Zhuhai, China

March

4th, Women In Data Science, Stanford University, Stanford, USA

5th – 6th, 5th Annual Big Data & Analytics Summit, Toronto, Canada

11th – 14th, 14th ACM/IEEE International Conference on Human Robot Interaction, Daegu, Korea

14th, AI 4 Business Summit, Brussels

14th – 15th, Data Innovation Summit, Kistamassan, Sweden

14th – 15th, Future of Information and Communication Conference (FICC), San Francisco, USA

18th – 20th, RPA & AI Summit, Copenhagen, Denmark

19th, Women in AI Dinner, Re-work, London, UK

21st – 22nd, AI on a Social Mission Conference, Montreal, Canada

April

9th – 10th, The Carnegie Mellon University – K&L Gates Conference on Ethics and AI, Pittsburgh PA, USA

18th, Applied Artificial Intelligence Conference, San Francisco, USA

24th – 26th, European Symposium on Artificial Neural Networks, Computational Intelligence and Machine Learning, Bruges, Belgium

25th – 26th, AI Expo Global Conference & Exhibition, Olympia, UK

26th – 27th, Artificial Intelligence: Thinking about Law, Law Practice, and Legal Education, Pittsburgh PA, USA

29th – May 2nd, Innovation Research Interchange 2019 Annual Conference – Innovation Unleashed: Physical Meets Digital, Pittsburgh PA, USA

29th – May 2nd, Strata Data Conference, London, UK

30th – May 3rd, Accelerate AI: Open Data Science Conference East, Boston, USA

May

2nd – 4th, SIAM International Conference on Data Mining (SDM18), San Diego, USA

6th – 7th, Predictive analytics World Industry 4.0, Munich, Germany

12th – 17th, IEEE International Conference on Acoustics, Speech and Signal Processing, Brighton, UK

16th, Rise of AI Conference, Berlin, Germany

20th – 24th, International Conference on Automation and Robotics, Montreal, Canada

22nd – 23rd, LDV Vision Summit, New York, USA

23rd – 24th, Deep Learning Summit, Boston, USA

June

2nd – 7th, Conference of the North American Chapter of the Association for Computational Linguistics (NAACL), Minneapolis, USA

3rd – 4th, Machine Learning Summit, San Francisco, USA

7th, 11th International Conference on Advanced Computational Intelligence, Guilin, China

10th – 11th, CogX, London, UK

16th – 21st, CVPR 2019: Computer Vision and Pattern Recognition, Long Beach, USA

18th – 21st, O’Reilly Artificial Intelligence Conference, Beijing, China

22nd – 26th, Robotics: Science and Systems, Pittsburgh, USA

22nd – 26th, Robotics: Science and Systems, Freiburg im Breisgau, Germany

chine is designed for a purpose, humans try to stop it, the machine is not equipped to change its mission. The system is designed to identify threats to it keeping it running.

chine is designed for a purpose, humans try to stop it, the machine is not equipped to change its mission. The system is designed to identify threats to it keeping it running.

You must be logged in to post a comment.